by Sam Fouche | Jan 2, 2023

Processing equipment & systems | Weighing & bagging systems

- Single-screw feeder

- Mostly used to dose micro ingredients

- The feed rate is either volumetrically or gravimetrically controlled from the control system (control system is not included and is sold separately)

- The micro dosers are manufactured in 304 grade stainless steel

- Load cells can be added

- Equipped with an agitator to prevent material bridging in the feeder

by Sam Fouche | Jan 2, 2023

Processing equipment & systems | Weighing & bagging systems

Mini batch weighing system

- Typical bagging capacities ranging from 100g to 2kg per bag

- PLC –based control system

- 2g accuracy

- High accuracy, automated weighing of granular materials

- Stand-alone or integration with processing plants

- Simple operation, easy to learn and use

- 24-hour local maintenance support

- IOT enabled

by Sam Fouche | Jan 2, 2023

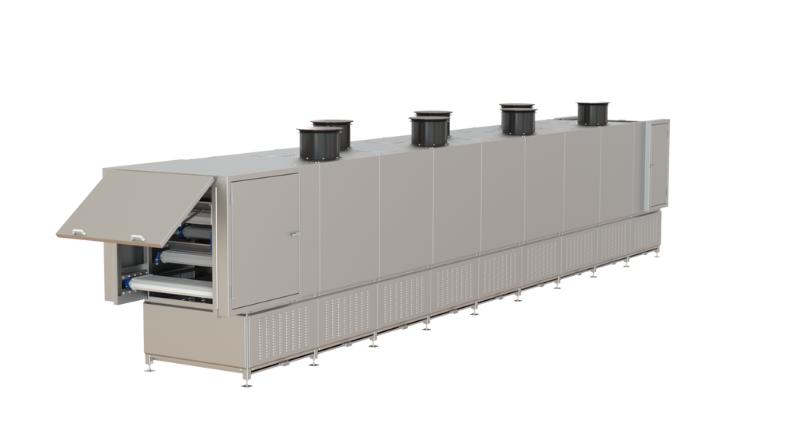

Processing equipment & systems | Drying & cooling systems

- 5 Stages each 10m travel through cooler – Total product travel +-50m

- 7 Axial flow fans – Total volume air flow 46500m³/h

- Product throughput 1000kg/h, depending on product

- Cooling of various products

- Different types of wire belts available for specific application

- Various mesh sizes available for different products

- Variable speed drive for different retention settings

- 4 lockable side panel doors for easy access during maintenance

- Large easy quick access doors at ends for cleaning

- Easily removable catch trays for cleaning

- Wire mesh belt & sprockets SS304

by Sam Fouche | Jan 2, 2023

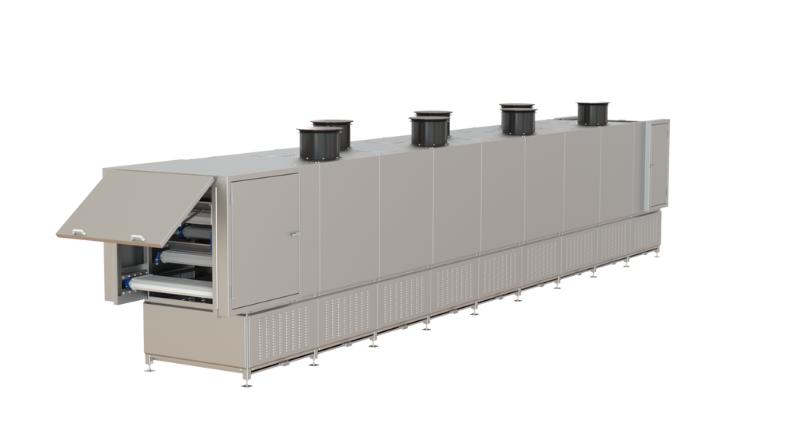

Processing equipment & systems | Drying & cooling systems

- Capacities of dryers are matched to the extruders’ capacities

- PLC system pre-loaded onto the system

- Operator-friendly interface

- Remote access and control

- Heating supplied using steam heating coils of gas fired burners

- Uniform heating and drying of products

- Products ranging from low bulk densities to high bulk densities

- Cereals, snacks, pet foods, aqua feeds, TVP, etc.

- Adaptability, with the versatility to dry a wide variety of products

- Modular design

- Robust and reliable design and construction through superior engineering and craftsmanship

- Hygienic design to enable toolless cleaning

- Low maintenance cost

- Maintaining high quality products with reliable consistency

- 24-hours local maintenance support

by Sam Fouche | Jan 2, 2023

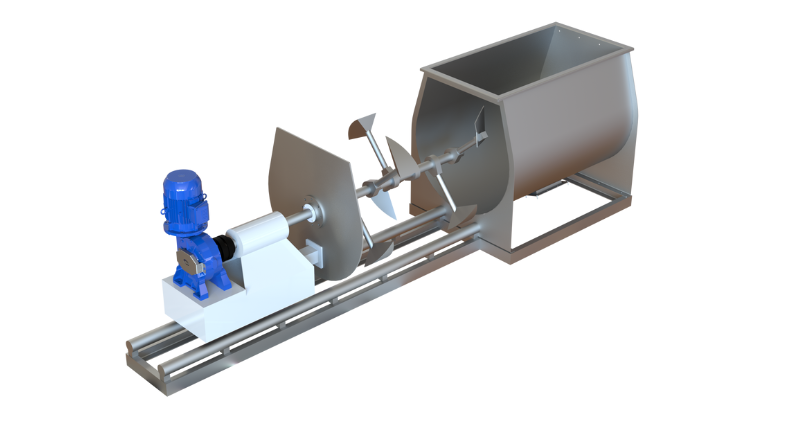

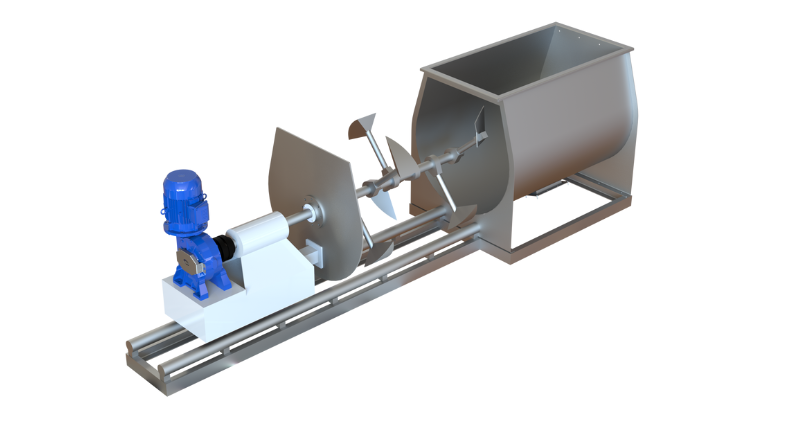

Processing equipment & systems | Mixing systems

- Production capacity from 1 tonne/hour upwards

- 1000l mixer volume

- Dust aspiration point on mixer lid

- Single shaft mixer with paddles

- No sharp corners to ensure effective cleaning

- High efficiency mixing of dry ingredients

- Can be used as stand-alone batching & mixing system

- Can be integrated with the control system of the processing plant

- High speed mixing due to effective mixer rotor design

- Mounted on load cells to facilitate accurate weighing of ingredients

- All food contact areas manufactured in 304 stainless steel

- 24-hour local maintenance support

- IOT enabled